OEM Manufacturing

An original equipment manufacturer produces equipment and parts for other companies over industries. With integrated supply chain, engineering techniques, years of experience, professional execution, quick prototyping, our specialists create parts that comply with your unique specifications.

CDG offers about 50 SGS-approved ergonomic furnishing & electronic peripherals items for you to choose from. Using die casting machines, auto-welding robots and other sophisticated automated production equipment, we produce LCD monitor mount, sit stand desk, computer & laptop workstation, phone & tablet holder and other ergonomic products. In addition, we make them all available for OEM/ODM customization in order to make sure our products suit your market perfectly.

CNC Machining Metalworking & Punch Press

CDG specialized in metal sheet fabrication including punching, stamping, shaping, folding and other metalworking. There are 70 punching machines with 60-400 tons punching capacity and average 300-400 tons steel consumption per month. The bending process takes place using CNC hydraulic press which can compress all types of materials. The two most common shapes are U and V while the metal can also be formed into corrugations, curls, flanges or other shapes.

With continuous improvement of processing capacity and efficiency in processing industry, the servo turret becomes the future trend by improving the tool change, positioning accuracy and stability while reducing environmental pollution caused by hydraulic turret.

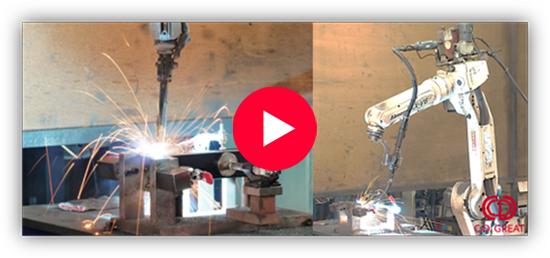

Bending, Reducing & Welding

Tubes and pipes are the major part of our most products. We support industries and applications in bending, reducing and welding various materials such as carbon steel, stainless steel or aluminum. The steel tube and pipe bender can bend outer diameter of pipe up to 65mm and maximum 2mm thickness of pipe with different shapes and angles even including irregular shapes.

Welding service in CDG deliver custom welding with modern machines and technology. The trained engineers provide precise and efficient manufacturing abilities choosing the right welding procedure to shorten turn around times & provide premium-quality results for your parts.

Die Casting & Investment Casting

Aluminum Die Casting / Cold Chamber Casting

Investment Casting / Lost Wax Casting

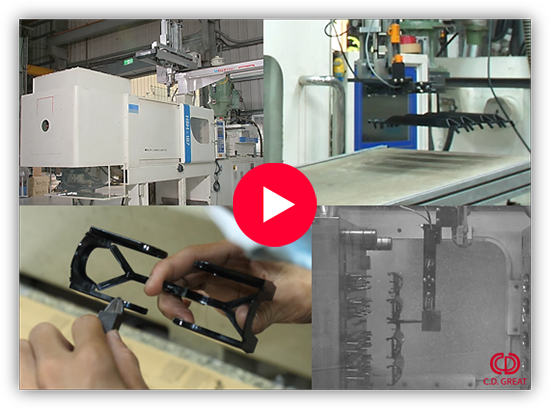

Plastic Injection Molding

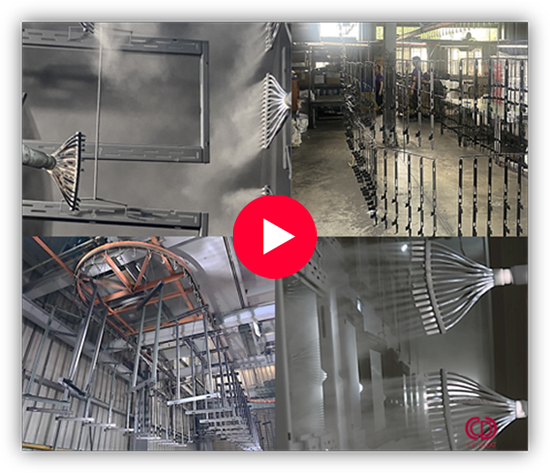

Automatic Powder Coating

Products from CDG are manufactured under a strict control program with ISO 9001 certified and awarded with Taiwan Quality Product Bravo Award. In order to meet each customer's expectation, every step of the manufacturing process is monitored under supervision including incoming material inspection, processing and product inspection, final-product inspection, packaging regular check-ups so that quality and safety standard is guaranteed. Additionally, our quality control inspecting team composed of well-trained professionals, we have our own Testing Lab facilities equipped with Projection comparator, RoHS Analyzer, fatigue, hardness and endurance capability testers to ensure the best quality provided. SOP is laid out in detail and strictly abided by each stage leading to proven efficiency and accuracy in mass production. Our mission is to provide high-quality products and efficient service with the most innovative designs and attractive prices to our worldwide customers.

CDG located in Taichung, Taiwan, the hub of the OEM industry which has mature metal, aluminum, plastic and wood board component processing supply chains. For more than a decade, we've been shipping goods to customers in North America, Europe, and Oceania. We keep expanding the customer bases to serve global users and customers. Our goal is to give variety of options while high durability of each of our product is ensured, easy installation and eye-catching appearance fulfilled.